Industry news

From the composition of wear-resistant steel ball analysis of its performance

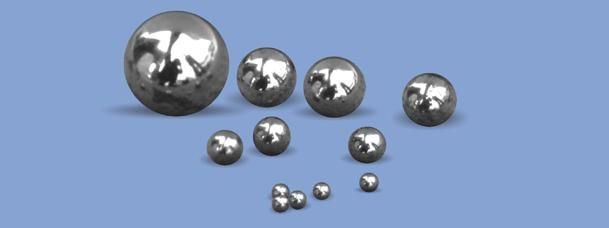

Steel ball production methods are generally forging, rolling, semi-solid molding and casting four categories. Due to the history of mining and dressing industry along with some special conditions of use and a comprehensive environment, background, in these industries, forging and rolling ball occupies a large proportion. Semi-solid molding is not unconventional casting, non-simple die-casting can explain the characteristics of a casting, forging, casting and forging the advantages of both the advanced technology formed by the outstanding performance caused the concern.

In general, wear-resistant steel ball in the industry is the most frequently used, the following simple analysis of the composition of wear-resistant steel ball composition:

Wear-resistant steel ball chromium content of 1% -3%, hardness HRC ≥45. This standard wear-resistant steel ball is called a low-chrome alloy cast ball. Low-chrome balls are produced by means of medium-frequency electric furnace melting, die casting or sand casting. Its performance is not suitable for grinding accuracy, wear and tear is not large in some of the metallurgical mines, slag and other industries.

Abrasion resistant steel ball light grinding is mainly to repair the cold heading process down the belt. Steel ball grinding process is mainly used to complete the two alloy castings. Through the two hard cast iron plate up and down the role of steel ball, cold forged steel ball ring, or the blank material in the blank grinding. The initial surface polishing mill.

0.9mm Miniature Steel Ball SS316L G100

Material: SS316/SS316L Stainless Steel Size: 0.9mm Grade: G100 Hardness: HRC25-39

4.7625mm Chrome Steel Ball G50

Chrome Steel Ball AISI52100/SUJ-2 Material: chrome steel AISI52100/SUJ-2 Size: 4.7625mm Grade: G5~G1000 Hardness: HRC62-

2.0mm Brass Ball G200

Brass BallMaterial: BrassSize: 1.5mmGrade: G200Certificate: ISO9001, TS16949, ISO14001Application: electric instruments,ABOUT US

Our Steel Ball Factory mainly focuses on high precision miniature steel ball manufacture and development. High precision stainless steel ball, chrome steel ball, glass ball and plastic ball, especially the size range from 0.5mm to 6.0mm, the precision up to Grade 5, are the main products we engage in.