Industry news

How to apply the load of steel ball

Ball mill rotary body is in its own gravity and the material left in the cylinder with steel ball gravity in the case of interaction with the bearing contact. Therefore, the application of load mainly has two parts, one is the gravity of the rotating body itself, and the other is the pressure exerted on the inner wall of the cylinder by the material in the cylinder and the steel ball under the action of gravity.

Apply gravity load

As mentioned earlier, in the solid modeling without the establishment of cylinder liner and the end cover, hollow shaft bushing and retaining ring, etc., so in order not to affect the calculation of steel ball, the application of gravity load, the need to The weight of the lining plate is added to the cylinder body and the end cap according to the equivalent density, and the weight of the bushing and the fixing ring inside the hollow shaft is added to the hollow shaft according to the equivalent density so as to realize the gravity compensation. The equivalent method is as follows:

(1) The cylinder (including the corresponding liner) has a weight of 147t and a volume of 9.4704m3, so the equivalent density is 15522kg / m3; (the density of the original cylinder material is 7850kg / m3)

(2) Each end cap (including the corresponding backing plate) weighs 46.5t, the volume is 3.377m3, so the steel ball equivalent density is 13770kg / m3; (the density of the original end cap material is 7850kg / m3)

(3) hollow shaft (including fixed ring, feed bushing, discharge bushing, etc.) 94t, the volume is 6.528m3, so the equivalent density is 14400kg / m3. (The density of the original hollow shaft material is 7850kg / m3)

2. Apply node load

The steel ball and material in the cylinder can be regarded as some equivalent isotropic body, and its upper surface is considered to be horizontal. Its positive pressure on the cylinder wall is proportional to the depth of the material layer. The weight of the steel ball and material can also be discretized into pressure values on the corresponding cell area.

Ball mill in the case of static load material and steel ball total weight of 400t, the loose proportion of 4.5t / m3, we can calculate the material depth h = 0.6285m.

In order to exert a variable surface load on the cylinder, a surface effect unit surf154 is established in the area where the cylinder body is affected by the material and the steel ball. The unit can be used for various load changes and surface effects. The surf154 element is then subjected to a varying pressure load at a pressure that is proportional to the height of the node in the active region at coordinates (referred to herein as the Cartesian coordinate system). Set the node depth zero material applied zero pressure, the proportion coefficient k.

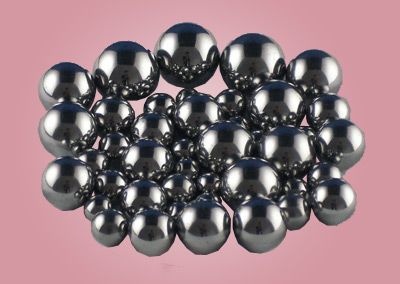

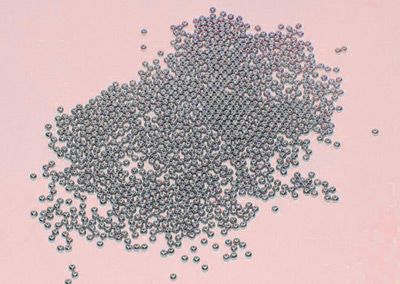

0.9mm Miniature Steel Ball SS316L G100

Material: SS316/SS316L Stainless Steel Size: 0.9mm Grade: G100 Hardness: HRC25-39

4.7625mm Chrome Steel Ball G50

Chrome Steel Ball AISI52100/SUJ-2 Material: chrome steel AISI52100/SUJ-2 Size: 4.7625mm Grade: G5~G1000 Hardness: HRC62-

2.0mm Brass Ball G200

Brass BallMaterial: BrassSize: 1.5mmGrade: G200Certificate: ISO9001, TS16949, ISO14001Application: electric instruments,ABOUT US

Our Steel Ball Factory mainly focuses on high precision miniature steel ball manufacture and development. High precision stainless steel ball, chrome steel ball, glass ball and plastic ball, especially the size range from 0.5mm to 6.0mm, the precision up to Grade 5, are the main products we engage in.